Solutions to Manufacturing Problems Found in Digitalization, Automation, and……."Location"

Challenges faced by manufacturing organizations across all industries include a significant skills shortage, regulatory pressures, unstable supply chains, and unprecedented uncertainties -- all of which are threatening the competitiveness of manufacturing enterprises. However, David Alatorre, Chief Technical Officer, Rivelin Robotics, writes that solutions do exist, and they can be found in digitalization and automation technology.

Despite recent advancements in industrial safety standards and protocols, manufacturing occupations are still associated with a multitude of health risks such as exposure to harmful substances, repetitive strain injuries, hand-arm vibration syndrome, dust inhalation, hearing loss, vision deterioration, and risks related to machinery accidents, fire, and electrical hazards. It is hypothetically possible to eliminate these risks through comprehensive safety measures; but, even then, trends suggest that this alone will not prevent the looming skills shortage.

Rivelin is leveraging robotics and AI to unlock a local-for-local production model in metal near-net-shape manufacturing.

Over recent years, the allure of traditional skilled workforce sectors such as manufacturing has been diminishing. Societal progression and technological development have been the catalysts in shifting the focus from manual, craftsmanship-based roles to those centred on digital skills and intellectual stimulation.

One of the key factors contributing to this shift is the rapid advancement of technology and digitalization across various industries. The digital revolution has created new and exciting opportunities in fields like artificial intelligence (AI), data science, software development, robotics and automation. These professions are attractive as they involve working with cutting-edge, innovative technologies to solve complex problems, and push through new boundaries. Organizations of all sizes increasingly rely on digital technologies to enhance their operations, improve efficiency, and gain a competitive edge.

Safety considerations are also a significant factor in career choices, along with physical exertion. As a result, traditional industries like manufacturing and construction are typically associated with being physically demanding and higher risk. For younger people entering the workforce, manufacturing jobs are less likely to attract them for the above reasons.

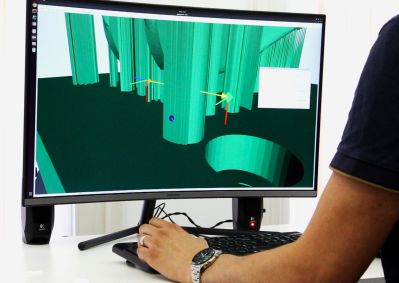

Digital tools like NetShape® make it easier to recruit the current generation of workers that seek digital skills and intellectual stimulation.

As a consequence, millions of physical and skilled positions remain unfilled, not necessarily due to salary constraints or flawed policies but because of a pronounced shift towards more fulfilling and safe professions.

Re-Industrialization of Western Economies

This skills shortage is only one among a growing list of factors escalating manufacturing costs. The manufacturing sector is grappling with a multitude of other challenges such as unstable supply chains shaken by global events, regulatory pressures tightening the requirements for quality and traceability, and unprecedented uncertainties. The combination of these factors leads to spiralling costs, threatening the competitiveness of manufacturing enterprises.

Some potential solutions to these challenges lie in the technological advancements of the last decade, particularly in automation technology. The convergence of advanced software tools, artificial intelligence and robotics offers a promising path towards re-industrialisation. As the experienced workforce edges towards retirement and the global west steers away from inexpensive foreign labor, manufacturing enterprises are turning to the digital paradigm; a world where humans shape ideas, and technology crafts them into reality.

Looking to the Future

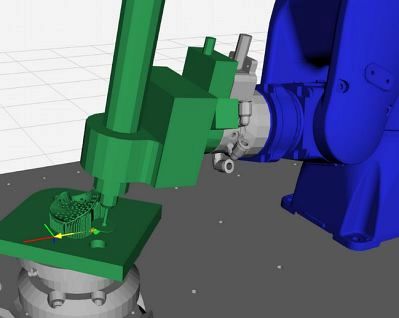

One such technology set leading the digital revolution in the manufacturing sector is Rivelin NetShape®, focused on metal near-net-shape manufacturing.

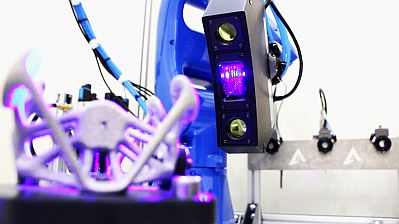

Digitizing craftsmanship requires the use of advanced sensors and algorithms that can adapt when faced with the unexpected.

Utilizing machine learning, advanced sensors, and proprietary algorithms, Rivelin's software engineers strive to encapsulate craftsmanship and intuition with the repeatability and traceability that industrial robotics provide.

NetShape® transforms skilled manual tasks into digital procedures that can be executed repeatedly, with minimal oversight, to produce high quality, finished metal parts. Rivelin's robots have already made significant strides in the casting and metal additive manufacturing sector, considerably boosting productivity and efficiency, reducing costs and eliminating high risk working conditions.

Rivelin's focus is on delivering a sustainable manufacturing future for businesses, their people and the planet. Digital innovation (and progress) is not a threat to manual jobs in manufacturing, it offers a new paradigm, one focused on humans shaping ideas and technology crafting them -- safely, efficiently and sustainably.

Rivelin NetShape® and automation platforms like it will be instrumental in unlocking sustainable "local-for-local" production around the world. This paradigm involves creating localized digital production ecosystems powered by automation technology where products are manufactured near the locations where they will be consumed.

Rivelin NetShape® software recognizes variability and generates intelligent finishing paths to compensate.

Advanced manufacturing technologies enable this shift for industries like aerospace, defense, energy and medical, where part complexity, small batch sizes and skills requirements drove manufacturing overseas to begin with. By focusing on local production, companies can increase efficiency, responsiveness and resilience while cutting costs, reducing emissions and supporting regional economies.

Conclusion

There are critical issues plaguing the manufacturing sector, ranging from a significant skills shortage to unstable supply chains, regulatory pressures and unprecedented uncertainties. The situation necessitates urgent innovative solutions to maintain the competitiveness of manufacturing enterprises.

Automation and digital manufacturing technologies such as Rivelin NetShape® can help address these issues. By capitalizing on machine learning, advanced sensors, and proprietary algorithms, these digital platforms transform skilled manual tasks into repeatable, efficient, and safer digital procedures. This not only boosts productivity and reduces costs but also makes the manufacturing sector more appealing to a digitally oriented, safety-conscious workforce.

Rivelin uses standard finishing tools like belt sanders, micro grinders, ultrasonic polishers, nippers and pneumatic hammers -- only manipulated by a robot.

The unfolding digital revolution in manufacturing is painting a future where robotics and AI can significantly alleviate the demands of manual labor. It enables the transition to a "local for local" production model, where goods are manufactured close to their intended customers, promoting regional self-sufficiency and reducing supply chain vulnerabilities. The digitalization of the manufacturing industry has profound implications, particularly in reindustrializing western economies, enhancing resilience, and diversifying supply chains.

In conclusion, as societal, technological, and economic dynamics continue to evolve, embracing digitalization and automation technology in manufacturing emerges as an effective strategy to navigate and mitigate the challenges confronting the sector. It lays a sustainable foundation for the industry, marrying human creativity with technological precision to ensure a safer, efficient, and productive future for manufacturing. The journey from manual craftsmanship to digital procedures is not merely a transition but a transformation offering immense possibilities for businesses, workforce, and economies at large.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::